Micro-Optics: Diversity of Shapes is Driving Progress

Simulation and innovative photonic manufacturing processes are paving the way for micro-optics to achieve an almost limitless variety of shapes. In this way, they are becoming a key technology of highly integrated photonics, with which the limits of what is feasible can be overcome.

The question itself is bold: “Can biological molecules or even living cells be captured, measured or modified with the help of light?” Arthur Ashkin answered this by developing optical tweezers, for which he was awarded the Nobel Prize in Physics in 2018. Since then, researchers worldwide have been striving to optimize this groundbreaking idea and make it widely available to scientific laboratories.

Micro-optics printed directly onto optical fibers

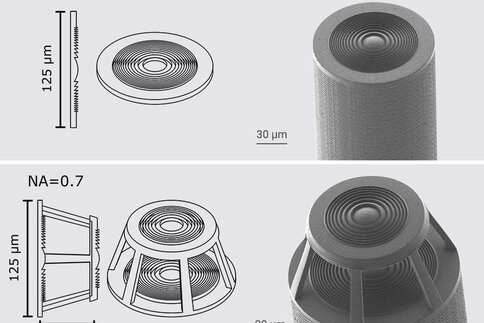

One key to this is specially shaped micro-optics. They focus the light from two exactly opposite laser beam sources on the point at which the tweezers are to fix the molecules or cells. This works because the tiny particles have a different refraction index from the surrounding medium. As soon as the fixed particle goes out of focus, the light is refracted, resulting in momentum transfer, which pulls it back into focus. To achieve beamforming with the necessary precision without the light intensity reaching cell-damaging levels, a team from the Department of Physics at the University of Stuttgart uses 3D printed micro-optics, which is directly printed onto the optical fibers with the aid of two-photon grayscale lithography from Nanoscribe. The high-precision focusing of the opposing laser beams was achieved using an optical system developed in-house which expands the light beam at the end of each fiber; this is then focused on the target point, using two diffractive Fresnel lenses arranged 60 micrometers apart. Only by using this trick was it possible to achieve the high numerical aperture that was required.

On the other hand, this trick was possible only because of Nanoscribe’s high-precision 3D printing process. In order to be able to print the Fresnel lenses, which are held apart by tiny columns, onto the fiber ends with high precision, a manufacturing strategy from Nanoscribe was used which automates the spatial alignment of the printed optics on the fiber cores. The micro-optical coupling with the Quantum X align technology, which was presented at LASER World of PHOTONICS in 2022, not only enables precise 3D printing of micro-optics onto glass fibers, but also onto photonic integrated circuits (PICs).

Here, a new manufacturing and product world is opening up in the microcosm. In addition to established companies such as Jenoptik, Suss MicroOptics or Mikrop, startups, such as Printoptix GmbH—a result of the Stuttgart project—and Glassomer from Freiburg, Germany, the winner of the LASER World of PHOTONICS Optics Fabrication Award 2022, are contributing. The latter cooperates with Nanoscribe to develop optimized photoresists for their two-photon polymerization—the building material of individualized micro-optics from the 3D printer. Thanks to the production flexibility, they offer developers nearly unlimited freedom in the shaping process. The free-form optics and prisms have been perfected in simulations, and can be realized one-to-one using the light-based additive process.

Photonics entering new markets

The EU-sponsored project PHABULOµS (see interview) aims to make free-form micro-optics usable for various industries. The range of applications includes free-form optics specially adapted to the short distance to the eye for virtual, augmented or mixed reality glasses. In addition to these lenses, which are known in the industry as “free-form multi-channel light folding optics”, free-form micro-optics also hold promise for automotive headlights or soft ambient interior lighting. According to SUSS MicroOptics, which is involved in the PHABULOµS project, free-form micro-optics are a key technology for mega trends, such as 5G, the Internet of Things, miniaturization in the healthcare market and automated driving.

Among other things, the Swiss company manufactures refractive and diffractive micro-optical solutions that combine micro-lenses and prisms in a single component for precise beam steering. Among other things, these are used for the coupling and decoupling of light signals in wafer-based PICs (photonic integrated circuits), which are one of the core components of silicon photonics. That’s because, in information and telecommunication technology, they enable increasingly higher bandwidths while at the same time reducing energy requirements, because the conversion processes of optical signals transmitted via fiber into copper-based electronics is eliminated; since optical data transmission produces significantly less waste heat, cooling requirements are reduced and makes it possible to realize systems on increasingly small spaces. The direct connection of lenses and prisms not only forges new paths for integrated photonics, but thanks to the precise beam guidance in a very small space, this also enables more compact sensor technology for wearable analysis and diagnosis devices: When light can be guided from the beam source to the detector via the shortest possible path through the medium under investigation, sensor systems can even be integrated into wearables.

With their monolithic co-integration of micro-lenses and prisms, the experts at SUSS MicroOptics are setting their sights on another large future market: Thanks to the minimal space requirements and comparatively inexpensive, easily scalable fabrication, the technology is suitable for the critical beamforming and directional elements of LiDAR sensors for autonomous vehicles. This would be the icing on the cake; after all, in order to be used in cars, they have to function reliably for the entire life of the vehicle, even under the most adverse environmental conditions—and need to boast minimal size and weight as well as costs compatible with the mass market. Only then will laser-based environmental sensor technology find its way into the autonomous vehicle of the future.