Integrated photonics: compact solutions for the connected world

Integrated photonics is revolutionizing data processing, communication and sensor technology with miniaturized, high-performance photonic chips. At Laser World of Photonics, you will experience how compact lighting technologies are setting new standards in efficiency, speed and application diversity – from quantum computing to telecommunications.

Light instead of electrons: How integrated photonics is changing everything

Some experts describe them as a silent revolution. Others see integrated photonics as an “emerging technology” with the potential to transform whole industries. But what exactly makes this young technology a game-changer?

The short answer is that, thanks to the high level of integration, in many applications there is no need to convert electronic signals into optical ones—and vice versa. This turns optoelectronic systems into purely optical ones.

This has many advantages: Transmitting the signal via light instead of via electrons is much faster and more energy efficient. Instead of feeding in electrons with limited bandwidths and high levels of heat loss in copper cables, intelligently modulated light can transfer lots of different information at the same time via the same waveguide.

Integrated Photonics Area in Hall A2

The Integrated Photonics Area offers the integrated photonics community a networking, exhibition, and information area. The Applications Stage will feature presentations on topics such as telecom/datacom, artificial intelligence, semiconductor LiDARs, and medical sensors.

Highest level of speed and energy efficiency with integrated optics

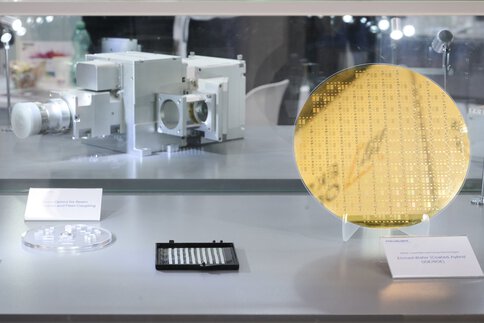

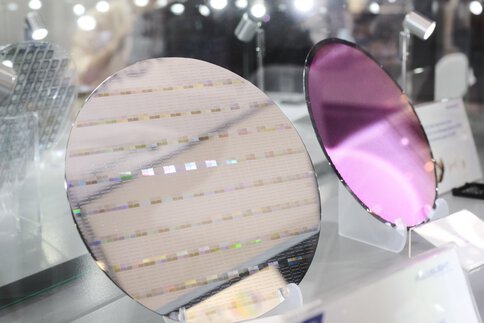

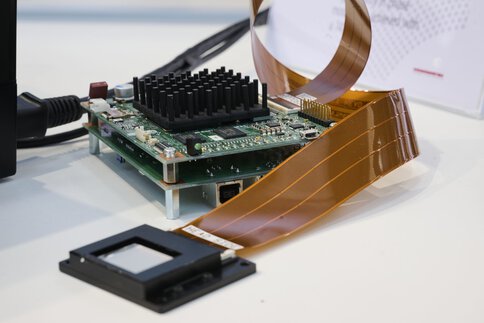

In order to make the most of this potential, laser/LED light sources, waveguides, modulators, converters etc. that were previously separate, connected to the optoelectronic system by various coupling points, are integrated on one chip. In the trade, they are known as photonic integrated circuits (PICs). Similar to electronic circuits on semiconductor chips, PICs integrate complex photonic circuits on silicon chips that are inexpensive because they are mass-produced.

Integrating all the necessary optical components, from the beam sources to the transistors, memory, modulators, polarizers and detectors, on one chip is the key to purely optical information processing and transferring at previously unimaginable speeds and levels of energy efficiency. And on top of that, many of the materials used, as well as established production technology and the division of labor production processes in the semiconductor industry, can be transferred to the manufacture of PICs. This also contributes to the rapid triumph of the technology, which has been seemingly unstoppable for several years.

Exhibitor directory

The Laser World of Photonics exhibitor list is ideal for looking up specific information on any exhibitor.

Integrated photonics for companies: highly relevant for many industries

Lasers that feed circuits with photons instead of electrons, which transport waveguides that are incorporated lithographically into chips with no loss; converters that no longer convert electrons and photons, but instead bring light signals to different wavelengths to create separate channels: This makes highly efficient information and communication technology a reality. Thanks to integrated photonics, the enormous cooling requirements of data centers and electronic high-performance chips are reduced to a minimum, although bandwidths are increasing exponentially at the same pace. All major chip manufacturers and data center operators now rely on integrated photonics.

More than communication: Integrated photonics conquering new markets

And this by no means covers the range of applications. Because this young technology goes hand in hand with minimal heat generation, miniaturization and integration, PICs are also in demand among manufacturers of sensors, mobile devices, LiDAR systems for autonomous vehicles and aircraft, as well as in the aerospace industry and in medical technology. Research institutes and start-ups all over the world are driving the development forward at full speed.

Integrated Photonics Area at Laser World of Photonics: rethinking lighting technology

In the Integrated Photonics Area of Laser World of Photonics 2025, leading companies, research institutions and technology pioneers will meet to present the latest solutions and fields of application. Take the opportunity to network with trade visitors from key industries such as information and communication technology, sensor technology and IoT, the automotive and aviation industry, and medicine and diagnostics – and actively help shape the future of integrated photonics!

Photonics industry portal & Newsletter

Explore the latest trends and innovations in the photonics industry. Our industry portal provides insights, expert interviews, and current news you won't want to miss.

Stay regularly informed about the most important and latest news in the field of photonics with our newsletter.