Imaging—one of the factors driving progress

Thanks to rapid technical progress, image processing technology is now being used in more and more sectors—and displaying its huge potential for innovation.

When red-hot rolled steel shoots out of a machine at a speed of 13 meters per second, the human eye cannot keep up. It is not designed to check technical surfaces with nanometer precision either. And if the quality of almonds, berries or apples needs to be checked on fast-running conveyor belts in the food industry and all traces of shell, stones and bruised or rotten fruit need to be removed, humans will soon find themselves overstretched, tired and unable to do the job to an adequate standard.

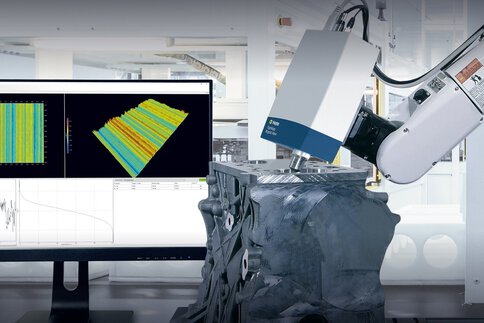

Modern machine vision solutions can help—and not just when it comes to the applications described here. The range of applications is growing all the time. High-speed camera systems break down extremely fast production processes into hundreds of high-resolution pictures per second—identifying possible sources of error precisely and reliably. Together with white light interferometers, camera systems mounted on robotic arms measure functional surfaces with height resolutions on the micrometer or even nanometer scale inline—at the relevant clock frequency during the process. As a result, specialists are no longer required to collect and evaluate the high-precision measurement data. Software guides users through the purely optical, contactless measuring process. Cylinder running surfaces can be checked, as can the microstructures on wafers. And when berries, nuts or apples are being selected, hyperspectral imaging can see what the human eye and monochrome or RGB camera systems cannot. By analyzing specimens in dozens or hundreds of spectral bands beyond visible light, they detect foreign bodies and pieces of shell just as reliably as they detect the early stages of rotting or bruising hidden under the peel. The systems are now so powerful and offer such high resolution that they can detect tiny flaws measuring just 0.5 mm on a conveyor belt with a width of one meter. Because they determine the positional data of the relevant berry or nut too, robotic arms can grab and remove it quickly and reliably.

Three-dimensional, hyperspectral and intuitive

The range of applications is not restricted to production and food-related processes. From sorting refuse, medicine, autonomous driving, the precise data-based use of fertilizers on cereals, automated apple harvesting or cashless shopping to optically identifying tiny bacteria with fluorescent nanosensors, checking minuscule chip structures or photographing galaxies light years away: imaging is driving progress and paving the way for a 100 percent quality-monitored, automated production world. There are many reasons why image processing offers potential in so many different areas. These include the falling prices of components, software and engineering. Many of today’s machine vision solutions can be operated intuitively and can be set up even by people with no specialist knowledge. This has helped to overcome the reservations held by many users. Once they are in use, the systems quickly prove their worth. Process efficiency increases, while the error rate falls. And unlike in “blind” automation where only a previously programmed process can be repeated, camera-assisted automation increases flexibility. Modern systems can grab unsorted parts from boxes, turn them so that they are in the correct position and then place them in machines as specified. In the process, they make no errors and never get tired. Machine vision solutions can even handle small quantities of different parts or individual items with ease—making the technology ideal for the personalized production world in Industry 4.0.

Rapid progress—whether it be interfaces, image sensors or AI

The rapid progress being made in the area of image sensors and graphics processors and the rapidly increasing bandwidths thanks to new interface standards such as 100GigE, CoaXPress or CameraLink HS fibre are contributing to the great success of machine vision. The range of 3D image sensors is increasing, and camera manufacturers are now spoiled for choice with increasingly high-resolution time of flight (ToF) CMOS sensors from various manufacturers, sensors based on laser triangulation, stereoscopic approaches or 3D solutions based on strip light projections. To ensure that the increasing data volumes remain manageable (the first streak cameras record around one terabyte per second), the sector is working on solutions which will allow the cameras to be operated in an event-based manner with the help of integrated intelligence. Their pixels are activated only if necessary, thus drastically reducing the amount of data produced. This will also be necessary given the new ultra-high-resolution cameras with over 100 megapixels.

The trend towards using artificial intelligence (AI) when evaluating data is another way to elicit as much information as possible from the huge quantities of data. Some AI-assisted cameras already feature suitable deep learning units. At the same time, start-ups are producing light field-based imaging systems in combination with intelligent algorithms—systems which can be used in quality monitoring in automotive production almost immediately even though they are not yet fully developed. The rapid technological progress in the imaging sector is taking place on a broad front. After four decades, what is essentially a photonic technology is now an indispensable standard in many sectors. Because it is becoming easier to combine different imaging procedures—for example 3D scanners and laser doppler vibrometers for analyzing vibrations in vehicle bodies—what could not be measured in the past can now be measured. Because the new findings are often used to optimize simulations, machine vision is leading to control loops which allow reality to be depicted virtually in an ever more exact manner. And this is where the next imaging megatrend comes in: allowing these virtual depictions to be experienced via virtual, augmented or mixed reality. This too is a photonic technology whose enablers will get together at LASER World of PHOTONICS in Munich from April 26–29, 2022.