Lasers dive deep

They cut and weld underwater, enable material analyses at the bottom of the deep sea and help to research the fauna there: Lasers are also a key technology in maritime applications.

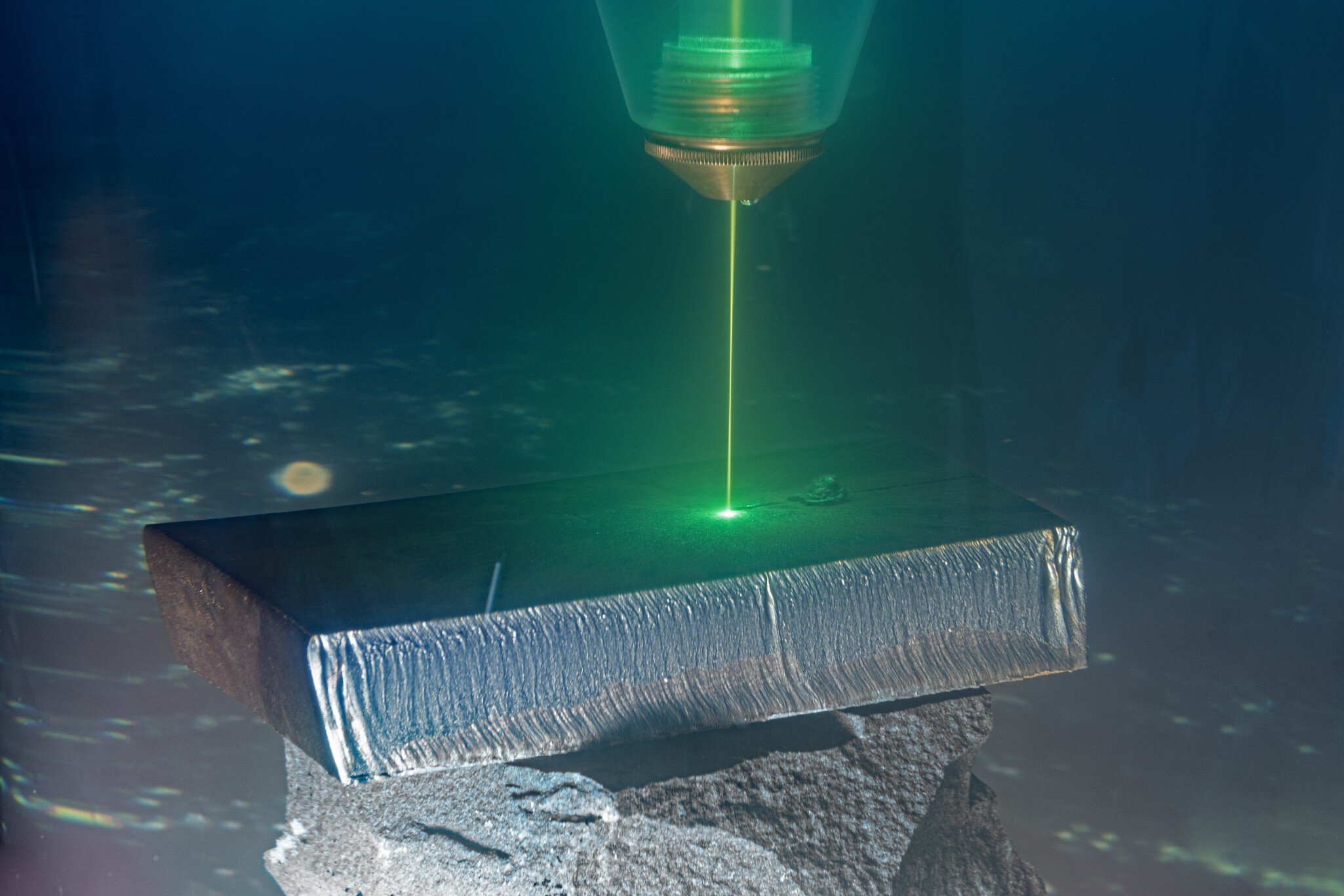

“Water makes up 70 percent of the Earth’s surface. In future, humanity must make greater use of these offshore reserves in order to develop and expand environmentally friendly energy sources,” says Prof Christoph Leyens, Director of the Fraunhofer Institute for Material and Beam Technology IWS in Dresden. To this end, his institute is driving forward new processes for the underwater laser processing of metals. Foundations of offshore wind turbines, harbor protection systems, sheet piling, barrages, locks or even pipelines can be processed directly in the water. Another field of application is the dismantling of disused nuclear reactors, in which laser processes gently dismantle steel structures under water while dissolving as little radioactive material as possible.

Laser cutting under water requires green or blue lasers. This is because the long-wave lasers used on land scatter too strongly in water. Their energy fizzles out. In contrast, short-wave lasers remain focused under water. Ever since manufacturers such as Trumpf, Coherent, Laserline and NUBURU started offering green and blue lasers with power in the kilowatt range, laser cutting under water has been an efficient, low-maintenance alternative to the mechanical cutting processes previously used. Unlike on land, no external gas supply is required: the water drives the molten metal out of the kerf. Water, which by itself is a hindrance, is turned into a benefit. Eliminating the gas supply in particular is an important prerequisite for compact, maneuverable underwater robots. “We are currently running tests with thicker materials and higher laser power,” reports Dr. Madlen Borkmann, group manager for laser cutting at the Fraunhofer IWS.

Cutting, welding, and cleaning ship hulls

Underwater laser processing is also high on the agenda at the Laserzentrum Hannover (LZF). Its “Underwater Technology Group” develops innovative laser processes for maritime applications in special pressure tanks for deep-sea simulation, in the underwater technical center in Hanover and in test areas on the North Sea island of Helgoland. This includes the self-shielded flux-cored arc welding of metal as a continuous laser process directly from the wire reel; it is an alternative to the established manual electrode welding process, in which electrode changes frequently interrupt the dipping process. The LZH is also developing low-contamination underwater separation processes for the dismantling of decommissioned nuclear power plants.

Together with partners such as the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM and Laserline, the LZH is also developing an environmentally friendly laser process for cleaning ship hulls. Laserline provides blue diode direct emitters that are used to irradiate them and remove shells, algae and other organisms. The hull fouling not only increases the flow resistance and thus a ship’s fuel consumption, but also threatens ecosystems by introducing new species.

The process kills the fouling with short-wave laser radiation without damaging the coating of the hull. The dead organisms are detached by the water current during the next trip at the latest. Automation is currently on the agenda: The laser system is to be mounted on a magnetic crawler in order to scan and irradiate the ship’s hulls under water. These crawlers are usually used on dry docks. The project is now adapting the technology to underwater laser treatment.

Detecting raw materials in the deep sea

Lasers will also help to explore the deep sea in the future. To date, the enormous pressures and absolute darkness have prevented humankind from exploring this part of our planet in detail. In fact, many planets are mapped in higher resolution than the depths of the oceans. But photonics is also creating new possibilities here. Among other things, it is about the exploration of raw materials on the seabed. In collaboration with the Leibniz Institute for Plasma Science and Technology (INP) in Greifswald, the LZH is further developing the LIBS (Laser Induced Breakdown Spectroscopy) method for this purpose. The analysis method, which is well-established in the aerospace and recycling industries, sends short, high-energy laser pulses onto materials, under the influence of which plasma is formed. Spectroscopic analysis of this makes it possible to determine the exact composition of the material. The research team has developed a new double-pulse technique in order to be able to use the process in deep-sea conditions. A first laser pulse creates an air bubble on the material surface, in which a second pulse vaporizes the material into plasma, which is then read out via spectroscope. Although simple in concept, the process is made complicated by the pressure conditions in the deep sea. It comes down to the meticulous interplay of pulse energy, pulse duration and the distance between the two pulses in order to generate meaningful spectra with suitable intensity.

LIBS in the deep sea is also the subject of a research team from the Chinese Academy of Sciences. It takes a different approach to generating laser-induced plasma under the enormous pressure at the bottom of the oceans. The team directs helium at high pressure onto the surfaces of the materials under investigation. In the gas, they use high-energy lasers to generate meaningful spectra for LIBS analysis. The project is part of China’s “National Key Research and Development Program” and points to the strategic importance of exploring for raw materials in the deep sea. This is because large quantities of valuable minerals and metals are stored there, which are needed for electric mobility and the expansion of renewable energies, among other things.

Unknown fauna and unexplored ecosystems

The use of LIBS is intended to make it possible to analyze the material composition of rocks and nodules on site in real time. Instead of costly sampling with submersible robots and laboratory analyses, or in place of the large-scale raking for potential raw materials, laser analysis could enable a targeted, gentle search for raw materials. Subsequently, extraction could be limited to areas where it is worthwhile. Otherwise, there is a risk of a scenario in which deep-sea ecosystems are damaged or even destroyed before their biodiversity is recognized and understood.

Parallel to the exploration of raw materials, research teams are endeavoring to shed light on the eternal darkness of the deep sea—and to study the fauna living there. They also use lasers for this. In this case, long-wave red light sources are helpful because they are imperceptible to the animals living there. As a result, they remain undisturbed, which enables researchers to observe and understand their natural behavior. Coherent has supplied the laser beam source for such a project by the Monterey Bay Aquarium Research Institute (MBARI). It provides enough light to record videos at depth and explore the creatures living there. Other teams are using photonic methods such as Raman spectroscopy and laser-induced native fluorescence (LINF) to analyze the mineral and organic suspended matter in the various water depths and on the seabed. It is about a fundamental understanding of the ecosystems, interconnections and material cycles of life. Photonics is a key technology for achieving this. This is because it enables large-scale, real-time analyses directly on site. This saves time that researchers previously had to spend on selective sampling and transportation to laboratories.